Chart time:

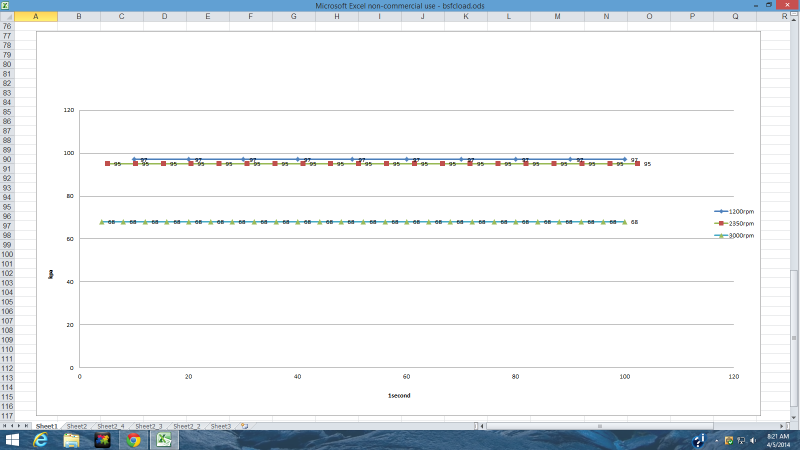

In the above chart is some data from my logs of my car last year.

The engine is a 2.0L 85mm bore, 88mm stroke

The lowest line in the graph is at 3000 rpm

-9.36 inch/hg or 68 kpa (L) more pumping loss

3.94 lbs/min of air (N/A)

12.81 bsac (L) less power from air

25 engine cycles/sec (L) greater pumping losses, lower kpa at the intake valves

21 a/f ratio (L) raises pumping losses

15.7 whp (L) more power needed for higher mph

0.61 bsfc (L)

28.8 fps piston speed (W) great air/fuel mixture

35mpg @ 66mph (L)

The middle line in the graph is at 2350 rpm

-1.59 inch/hg or 95 kpa (W) less pumping losses

3.13 lbs/min air (N/A)

16.80 bsac (W) more power from air

19.5 cycles/sec (W) lower pumping losses, higher kpa at the intake valves

30 a/f ratio (W) lowers pumping losses by increasing higher load needed for the correct fuel amount for power output.

9.5 whp (W) lower power needed for lower mph

0.56 bsfc (W)

22.6 fps piston speed (W) fast enough to promote good air/fuel mixture

53mpg @ 53mph (W)

*Comparing between the two lines.

(W) win

(L) lose

Now there is the third line, the highest in the graph at 1200 rpm.

FAIL

-1.02 inch/hg or 97 kpa (W) low pumping losses, great kpa at the intake valve

10 cycles/sec (L) very low air velocity killing air flow, and causing reversion

11.5 fps piston speed (L) major knock, from slow power stroke, and heat adsorbed into combustion chamber cylinder etc.

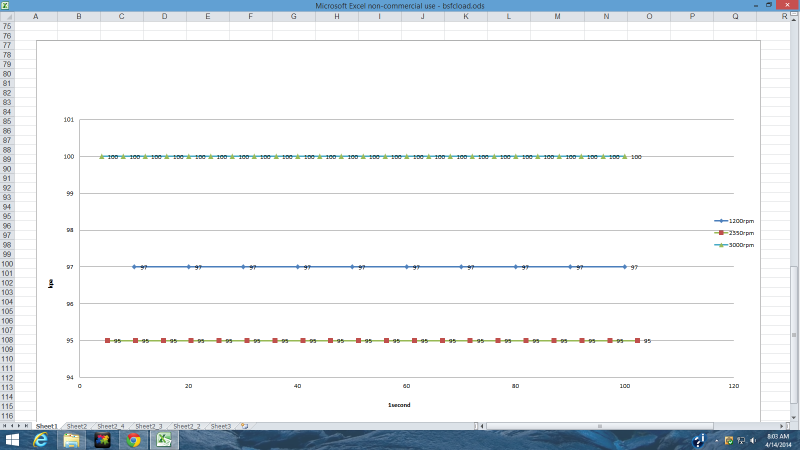

This is my goal for this year.

3000 rpm @ 225*F+ IAT

-0.01 inch/hg or 100 kpa (W) no pumping loss

4.53 lbs/min of air (N/A)

14.7 bsac (W) more power from air

25 engine cycles/sec (W) high air velocity, no pumping losses, highest kpa at the intake valves

30 a/f ratio (W) lowers pumping losses

15.7 whp (W) more power needed for higher mph

0.49 bsfc (W)

28.8 fps piston speed (W) great air/fuel mixture

47 mpg @ 70 mph (W)

I'm building a high temperature air injection unit that will inject air 3" in front of the intake valves. I will be able to adjust the injection injection angle at the intake port. I'm also building a adjustable cool air EGR flow valve. This will be up-stream from the high temperature ports. My EGR system will will have its own cooling system so I will be able to control EGR temperature.

On my car the stock EGR was just along for the ride. It never was enable from the factory. The 1991 California Talons were the only cars with active EGR systems.

In this pic you can see EGR, its outlet is at 6:00 O'clock at the bottom of the T/B placement.

I also have a electric vacuum pump that will keep the vacuum brake's happy so I will always have a stock feel to the break-pedal.

Intake port runner, showing injector angle. Air injection directed at fuel injector fuel flow path about 3" upstream.